Auto and Shop Information Study Guide for the ASVAB

Page 4

Shop: Measuring Tools

While technology has made significant strides in the automotive and workshop industries, introducing sophisticated machines and automated systems, the importance of traditional hand tools remains undeniable. Even as we embrace the digital revolution, these basic, manually operated tools continue to hold their ground as indispensable elements in every mechanic’s toolbox.

Calipers

Calipers are versatile measuring tools used to measure distances or diameters. They are available in different types, but those most commonly used in a shop are outside and inside calipers.

outside calipers—Used for measuring the external size of an object. The two legs that extend from the body and converge to a point are pushed apart to the size of the item to be measured.

inside calipers—Used for measuring the internal size of an object. Like the outside caliper, the legs of the inside caliper diverge from the point where they are connected to the body.

legs—The legs are the long parts of the calipers that do the actual measuring. They can be adjusted to fit around the object being measured.

friction joint—This is the point at which the legs of the caliper are joined. The friction joint allows the calipers to maintain their position relative to each other, once set by the user.

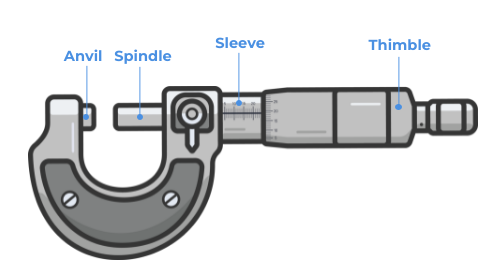

Micrometer

A micrometer, sometimes known as a micrometer screw gauge, is a device used for precise measurements. An “outside micrometer” is usually used for measuring the outer dimensions of objects.

spindle—The spindle is a cylindrical component that moves toward or away from the anvil. As the thimble is turned, the spindle moves correspondingly.

anvil—The anvil is a stationary component against which the object to be measured is placed. The spindle moves toward the anvil, enclosing the object.

sleeve—The sleeve is a stationary part of the micrometer that has markings along its length for measurement.

thimble—The thimble is a part of the micrometer that can be rotated. Each rotation moves the spindle toward or away from the anvil. The thimble has markings for more precise measurements.

Spirit Levels

Spirit levels, also known as bubble levels, are tools used to indicate whether a surface is horizontal (level) or vertical (plumb). There are two types of spirit levels: tubular and bullseye.

tubular spirit levels—These contain a slightly curved glass tube, which is partially filled with a liquid, leaving a bubble in the tube. The bubble moves to the highest point of the tube, indicating whether the surface is level or not.

bullseye spirit levels—These are circular and work on the same principle as tubular spirit levels. They can indicate the levelness of a surface in multiple directions at once.

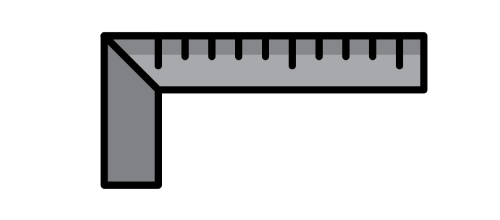

Steel Squares

A steel square, also known as a carpenter’s or framing square, is a two-armed device made from steel. It has a longer, wider arm known as the “blade” and a shorter one known as the “tongue,” and these two arms create a 90-degree angle.

blade—This is the longer, straight edge of the square, usually marked with measurements.

tongue—This is the shorter edge of the square, which is at a right angle to the blade. This is also usually marked with measurements.

Tape Measure

A tape measure is a flexible ruler used to measure size or distance. It consists of a ribbon of cloth, plastic, fiberglass, or metal with linear measurement markings. It is a common measuring tool for both professionals and DIY users because of its flexibility and portability.

Steel Rule

A steel rule is a straight, flat, rigid piece of steel marked with measurements along its length. It is used for drawing straight lines and taking measurements. It is more accurate than a tape measure for shorter lengths.

Shop: Striking Tools

Striking tools are fundamental to a variety of mechanical operations. They are primarily used to deliver impact force to an object. Here, we’ll explore different types of hammers, attachment devices, and other striking tools commonly found in a shop setting.

Hammers

Hammers are among the oldest and most frequently used hand tools. They are available in different types and sizes for various applications.

Ball-Peen Hammer

A ball-peen hammer has a flat face for striking and a rounded peen for shaping metal and closing rivets. It’s commonly used by mechanics and also in metalworking tasks.

Rubber or Wooden Mallet

A rubber or wooden mallet is used for delivering softer blows without causing damage, which is ideal for assembling parts, shaping sheet metal, or working with wood. A rubber mallet is typically used in carpentry, tile setting, and automotive work where a firm but non-damaging touch is required.

Claw Hammer

A claw hammer is primarily used for driving and removing nails. One side of the hammer’s head is flat for striking, while the other side is bifurcated, forming a claw for pulling nails. Similar to a claw hammer, a rough framing hammer is generally heavier and designed for heavy-duty tasks like framing houses, where a lot of force is needed to drive large nails into heavy lumber quickly.

Sledge Hammer

A sledge hammer, with its long handle and large, heavy head, is designed to apply significant force. It’s generally used for heavy-duty tasks like breaking concrete or driving stakes.

Pneumatic Nail Gun

A pneumatic nail gun uses pressurized air to drive nails into various materials. It’s a power tool commonly used in carpentry and construction.

Attachment Devices

Attachment devices like nails and rivets are fundamental for joining materials together.

Nails

Nails are one of the most common fasteners used in construction and woodworking. They consist of a head, shank, and point. The head is the part that’s struck with a hammer to drive the nail into the material. The shank is the long part or “body” of the nail, and it can be smooth, ringed, or spiraled, depending on the type of nail and its intended use. The point is the sharp end that penetrates the material.

Nails come in a wide range of sizes and types, each designed for specific applications. For example, finishing nails have a small, countersunk head and are used for finish carpentry and for fastening interior trim. Roofing nails, on the other hand, have a large, flat head and a short shank, and are used to fasten roofing materials.

Rivets

Rivets are mechanical fasteners that consist of a smooth, cylindrical shaft with a head on one end. They are used to join two pieces of metal or other material together permanently. The rivet is inserted into pre-drilled holes in the materials to be joined, and a second “head” is formed on the other end by hammering or using a rivet gun, causing the rivet to expand and securely hold the materials together.

Rivets were once very common in construction and were often used to build steel bridges and skyscrapers. Today, they are used less frequently in large-scale construction, but they are still commonly used in other applications, such as in the assembly of aircraft and in the production of clothing, luggage, and other goods.

Other Tools for Striking

Striking tools, such as chisels, punches, and drifts, form an integral part of any workshop, and their function is intrinsically linked to the use of hammers. These tools are designed to be struck by a hammer, translating the force of the impact into precise actions. Whether it’s carving away material with a chisel, marking or driving a nail with a punch, or aligning holes with a drift, these tools all depend on the kinetic energy delivered by a hammer. As such, understanding the relationships between these striking tools and hammers is essential for effective and safe work in various trades, from carpentry and masonry to metalworking and automotive repair. Let’s take a closer look at how each of these tools operates.

Chisels

A chisel is a tool with a sharp cutting edge that is used for carving or cutting hard material, such as wood, stone, or metal. Chisels are driven by a mallet or a hammer.

A cold chisel is a specific type of chisel made of tempered steel and used for cutting “cold” metals, meaning metals that are at room temperature. Unlike hot chisels, which are used on heated metal in blacksmithing and similar processes, cold chisels are meant for removing waste metal when a very smooth finish is not required.

Punches

Punches are tools used for driving or marking material. They are often used in conjunction with a hammer, which strikes the end of the punch. A pin punch is narrow and is used for driving out metal pins from a hole. A center punch is used to mark the center of a point. It is usually used to mark the location for drilling a hole. When struck with a hammer, it produces a small indentation that keeps the drill bit from slipping.

Drifts

Drifts are cylindrical or tapered tools made from soft metals like mild steel, brass, or aluminum. Drifts are used in a variety of applications, such as enlarging or aligning holes. A drift is often struck with a hammer to drive it into a hole or against a part. Because drifts are made from softer metals, they’re less likely to damage the parts they’re used with. They’re often used in automotive repair, metalworking, and other industrial applications.

Turning Tools

Turning tools are used for installing or removing fasteners and hardware, such as screws, bolts, and nuts. They facilitate the rotation of these objects, often utilizing torque (a measure of rotational or twisting force) to securely fasten or remove components.

Screwdrivers

Screwdrivers are specifically designed to interact with screws, which have a helical ridge known as a thread. Different types of screwdrivers are made to fit the different shapes of screw heads.

flathead screwdriver—Also known as a slotted screwdriver, this tool has a flat blade that fits into the single slot of a flathead screw.

Phillips screwdriver—This type of screwdriver has a cruciform shape, designed to fit into screws with a cross-shaped, or Phillips, recess.

Robertson screwdriver—The Robertson, or square-tip, screwdriver has a square-shaped tip and is used with screws that have a square recess.

Torx screwdriver—A Torx screwdriver has a star-shaped tip and is used with Torx screws, which are common in automobiles and consumer electronics.

screws—Screws are a type of fastener characterized by a helical ridge, known as a thread. They are typically used to hold objects together and in place.

Wrenches

Wrenches are tools used to provide grip and mechanical advantage in applying torque to turn objects, usually rotary fasteners, such as nuts and bolts.

open-end wrench—An open-end wrench has a U-shaped opening that grips two opposite faces of the bolt or nut. This wrench is often double-ended, with a different-sized opening at each end.

box-end wrench—A box-end wrench encloses the bolt or nut on all sides and is typically hexagonal. It provides more points of contact and thus lessens the risk of rounding off a fastener.

combination wrench—A combination wrench has an open end on one side and a box end on the other, offering versatile use.

adjustable wrench (Crescent® wrench)—This type of wrench has a “jaw” of adjustable width, allowing it to be used with a variety of nut and bolt sizes.

Sockets

Sockets are a type of wrench that fit snugly over a nut or bolt head. They attach to a socket wrench handle, typically via a square drive fitting.

six-point socket—A six-point socket has six points of contact, designed to match hexagonal nut or bolt heads.

twelve-point socket—A twelve-point socket has twice as many points, allowing for easier alignment with the fastener.

socket sizes—Sockets come in a variety of sizes to match the many different nut and bolt sizes. Common systems of measurement include metric and SAE (Society of Automotive Engineers).

ratchet—A ratchet is a type of wrench that uses a mechanism allowing the wrench to turn the socket in one direction but not the other, enabling efficient tightening or loosening.

pneumatic air impact wrench—This tool uses compressed air to generate high torque. It is typically used with impact sockets, which are made of tougher materials to withstand the force of impact.

Bolts

Bolts are a type of threaded fastener typically used with a nut. They differ from screws primarily in the way they secure materials. Bolts pass through pre-drilled holes and are fastened with a nut on the other side, while screws are typically turned directly into the material itself and secure items by the thread’s grip in the material.

Thread Pitch

Thread pitch refers to the distance between the threads on a bolt or screw. The thread pitch can be measured using a thread pitch gauge, a tool with teeth that match the various standard thread pitches.

Fractional Measurement Fasteners

Fractional measurement fasteners refer to bolts, screws, and nuts that are measured and sized in fractions of an inch, typically used in non-metric systems like the imperial system prevalent in the US.

unified national coarse (UNC)—UNC is a thread form with a larger thread pitch, which means the threads are further apart. This type of thread is often used in applications where assembly and disassembly are common.

unified national fine (UNF)—UNF is a thread form with a smaller thread pitch, which means the threads are closer together. This type of thread provides better load-carrying ability and is used in precision applications.

Other Bolt Measurements

In addition to thread pitch, other important bolt measurements include diameter and length.

diameter—This is the measure of the bolt at its largest point, not including the head. The diameter of a bolt is a crucial aspect of sizing and can be determined using a bolt gauge.

length—The length of a bolt is measured from the underside of the head to the end of the threads. Knowing the correct length is essential to ensure that the bolt fully penetrates and secures the materials.

Nuts

Nuts are integral components in the world of fasteners, typically used with bolts to secure materials together. Characterized by their internal threading, nuts are designed to correspond with the threading of a bolt, which enables a secure and tight connection. It’s crucial to ensure that the nut and bolt share the same thread type for proper engagement and safety. Here’s a closer look at some common types of nuts:

hex nut—This is perhaps the most common type of nut, with six sides that provide sufficient angles for a tool to grip.

wing nut—Recognizable by its “wings,” this nut can be manually turned without the need for any tools, making it useful in situations where ease of assembly and disassembly is key.

castellated nut and cotter pin—A castellated nut, also known as a castle nut, is a type of nut that includes a cylindrical extension on one end that contains notches. These notches accept a cotter pin, which prevents the nut from turning. This setup is used in applications where safety is crucial, such as automotive suspension components.

lock nut—A lock nut is specially designed to stay tightened despite vibrations that would loosen standard nuts. They’re used in applications where it’s essential the nut doesn’t come loose, such as machinery or vehicle wheels.

Each of these nuts serves a distinct purpose, and their selection should align with the application requirements for the most effective and safe results. Furthermore, nuts can only be used with bolts that have the same thread type, which ensures the proper engagement and security of the fastened components.

All Study Guides for the ASVAB are now available as downloadable PDFs