ServSafe Food Handler Study Guide for the ServSafe

Page 2

Time and Temperature

Food handlers must understand the importance of time and temperature and how time and temperature can either help keep food safe or lead to pathogen growth. This includes keeping hot foods hot and cold foods cold. The foods that need Time and Temperature Control for Safety are known as TCS foods.

The Importance of Time and Temperature

TCS foods are more prone to bacterial growth when left too long at the wrong temperature. Any food can become contaminated and unsafe, but TCS foods spoil more quickly and allow for dangerous levels of pathogen growth if not kept at the correct temperature. The presence of harmful pathogens could lead to foodborne illness.

The Most Vulnerable Foods

Foods that need time and temperature control for safety, or TCS foods, are the most likely foods for dangerous pathogen growth and for becoming unsafe. The most common TCS food types are:

- Eggs, milk, and dairy products

- Poultry, beef, pork, and lamb

- Fish, shellfish, and crustaceans

- Baked potatoes

- Cooked rice, beans, and vegetables

- Tofu and other soy protein, and textured soy protein meat alternatives

- Sliced melons, cut tomatoes, shredded lettuce, and cut leafy greens

- Sprouts and sprout seeds

- Untreated garlic and oil mixtures such as infused oils

The Temperature Danger Zone for Food

In order for TCS foods to remain safe, they must be kept at the proper temperature and out of what is known as the temperature danger zone. The temperature danger zone is from 41° F to 135° F (5° C to 57° C) and is the range in which pathogens grow exponentially. TCS foods must be kept either below 41°F or above 135° F. If you check the temperature of a food and it is in the temperature danger zone, you may need to cook it further, reheat it, or throw it out to maintain safety.

Measuring Food Temperature

Proper use of a food thermometer is necessary to make sure foods are at the correct temperature. Food thermometers are used to make sure cold food is cold enough upon delivery, and when in cold or freezer storage, and to make sure hot food is hot enough during cooking and before serving. Many establishments record these temperatures. It is important to use thermometers correctly.

Choose the Thermometer

Some tasks require a different thermometer. Ask your manager for the correct thermometer for the job.

Prepare the Thermometer

The thermometer should be calibrated before use in order to ensure an accurate reading. It should also be washed, rinsed, sanitized with an alcohol prep wipe, and air dried before use.

Use the Correct Procedure

When checking cooked meat, insert the thermometer into the thickest part, usually the center. Once the reading hovers at a steady temperature, write down the temperature and confirm the measurement by taking an additional reading in another spot.

After Using the Thermometer

Wash, rinse, sanitize with an alcohol prep wipe, and air dry the thermometer after use. Store it in its clean storage case.

Receiving Food

The food handler’s monitoring of time and temperature begins when food is received and continues through storing, thawing, preparing, cooking, and serving the food. Temperature must be controlled at all times. When receiving food, check for proper temperature, undisturbed packaging, and good quality. Poor quality may indicate the food has been stored at the wrong temperature.

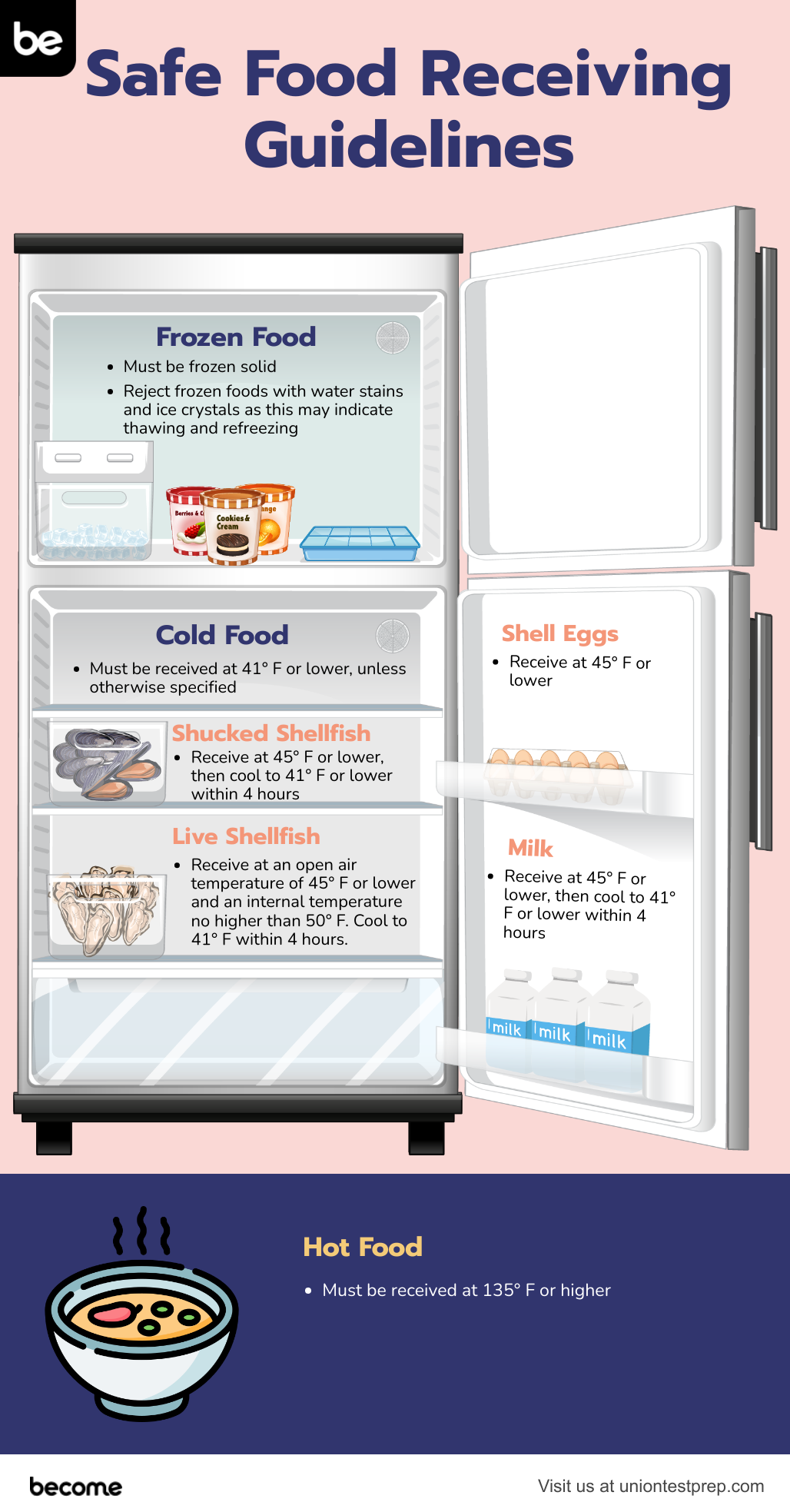

Cold Food

Cold TCS foods should be received at 41° F or lower and the manufacturer’s instructions should be followed.

Frozen Food

Frozen foods should be received frozen solid. Food products or packaging with fluids, water stains, or ice crystals should be rejected. Big ice crystals on frozen foods or packaging indicate something has thawed and been refrozen.

Hot Food

Hot foods should be received at 135° F or higher.

Other Reasons to Reject Food Delivery

Foods that arrive with out-of-date expiration or use-by dates, unusual color or mold, or an off smell should be rejected. Food handlers should also reject meat, fish, or poultry that is slimy, sticky, or dry.

Food Storage

After food is received it is put into storage, and could move in and out of storage. Time and temperature are crucial when storing food and must be monitored. Stored foods should have clear received-on and use-by date labels. Food that moves off-site must also be labeled and temperature controlled, This is also true for packaged foods for self-service. There are guidelines for safe food storage, labeling, and holding.

Storing Cold Food

Cold TCS foods should be stored at 41° F or lower. Frozen foods should be stored frozen. Never pack coolers or freezers too full, and plan your trips to the cooler or freezer so the door won’t be open for longer than necessary.

Containers and Labeling

Foods removed from their original packaging must be labeled with their common name. Ready-to-eat TCS foods should be marked if they are to be held over 24 hours, indicating the date the food must sell by, be eaten by, or be thrown out by. Ready-to-eat TCS foods prepped on site can be held for seven days as long as they have been held at 41° F or lower.

Off-Site Food Service

Some establishments cater, preparing and delivering foods to an event. This food must be kept out of the temperature danger zone during delivery. Insulated, food-grade containers will keep foods at proper temperatures. Off-site labels are needed and should include the food name, a use-by date and time, and reheating and serving instructions.

Food Rotation

Foods in storage should be rotated according to the first-in, first-out (FIFO) procedure to ensure the oldest foods are used first. Check use-by and expiration dates. Foods with the earliest date should be placed in front of foods with later dates. Use foods in the front first.

Thawing and Preparing Food

Foods taken from storage for thawing and preparation must be monitored. When a frozen food has to be thawed, or when TCS foods are being prepared, they are taken from their temperature-controlled storage and placed in the temperature danger zone, where they must be monitored carefully to ensure pathogen growth is under control.

Thawing

Foods must never thaw at room temperature. Thawing temperature has to be controlled, and there are only four correct ways to thaw frozen foods:

- In the cooler at 41° F or lower

- In a microwave (if the food is to be cooked immediately)

- Submerged under 70° F or lower running water

- As a part of the cooking process (such as a frozen hamburger patty)

The temperature of foods thawing under the running water must be monitored and never allowed to get above 41° F for longer than four hours.

During Preparation

Foods must also be monitored during preparation. Preparing TCS foods puts them directly into the temperature danger zone and it is unsafe for them to sit out too long. Never prepare TCS foods in large batches so ingredients are kept from spending too much time in the temperature danger zone. Return prepared TCS foods to the cooler as soon as possible.

Cooking Food and Beyond

After thawing and preparation, foods move to cooking, holding, cooling, and possible reheating. Time and temperature must be monitored during these stages by using the correct thermometer, and by minimizing the time foods spend in the temperature danger zone. There are guidelines for cooking, holding, cooling, and reheating foods.

Cooking to Internal Food Temperatures

Foods must be cooked to proper internal temperatures for the correct amount of time to reduce pathogens that may be present. Certain foods must reach a specific internal cooking temperature to eliminate pathogens commonly found in them, and to reduce the likelihood of foodborne illness.

- Poultry (whole or ground chicken, turkey, or duck) must reach 165° F for less than 1 second or instantaneously.

- Ground meat (beef, pork, and other meat) must reach 155° F for 17 seconds.

- Seafood (fish, shellfish, and crustaceans) must reach 145° F for 15 seconds.

- Pork, beef, veal, and lamb steaks or chops must reach 145° F for 15 seconds.

- Pork, beef, veal, and lamb roasts must reach 145° F for four minutes.

- Fruit, vegetables, grains (rice and pasta), and beans that will be held hot must reach 135° F for no minimum time.

At-Risk Populations

Some groups of people are at a higher risk of foodborne illness due to weaker immune systems. They include the elderly, preschool-age children, and anyone with a compromised immune system due to illness (such as chemotherapy patients). Hospitals and day care facilities have additional guidelines for these groups, so check with your manager for policy information.

Using a Microwave Oven

Microwave cooked meat, seafood, poultry, and eggs must reach 165° F. Microwave-cooked foods should be covered to keep their surface from drying, and rotated halfway to ensure even cooking. The cooked food should stand for two minutes to evenly disperse the temperature and should be checked with a thermometer in at least two spots to ensure it is cooked throughout.

Holding Food

TCS foods should be time and temperature controlled during hot and cold holding, which should take place in food-grade equipment such as steam buffet tables or refrigerated buffet tables. Hot foods must be held at 135° F or higher and cold foods must be held at 41° F or lower. Temperatures should be taken every four hours and your manager should be notified if a food is not at its correct holding temperature.

Cooling Food

Hot TCS foods must be cooled before entering cold storage. Never put a large container of hot food in the cooler, and never cool food at room temperature. The safest cooling methods are to: reduce the size of the food, submerge the container in an ice bath, stir food with an ice paddle, add ice to the food, or use a blast chiller. Foods must cool from 135° F to 70° F in two hours, then down to 41° F or lower in the next four hours. Foods that do not cool to 70° F in two hours have to be reheated and cooled again to control pathogen growth.

Reheating Food

Certain TCS foods have specific reheating temperatures. Foods that are reheated and then held for service, like soups, must reach 165° F for 15 seconds in two hours. Processed packaged food, like fried mozzarella sticks, must reach 135° F. Never use hot-holding equipment to reheat foods.

All Study Guides for the ServSafe are now available as downloadable PDFs